If you’re looking for information on the cost of a tire pyrolysis plant, you have come to the right place. In terms of numbers, expect to spend anywhere from $50,000 to more than $100,000 for a pyrolysis plant. Several factors affect its final cost. Having said that, buying a plant only based on its price is not the right way to choose the best plant for your business.

While pyrolysis plants are being set up everywhere, not everyone knows how to choose the right plant. Since there aren’t that many barriers to entry, many new entrepreneurs are trying their luck in this business. If you are also setting up a new pyrolysis plant, here is what you need to know about the factors that affect the tyre to oil plant cost.

Processing Capacity of the Machine

Processing capacity refers to the amount of material that can be processed at a time inside the pyrolysis reactor. Price increases proportionately with processing capacity. Many new buyers make the mistake of buying as much processing capacity as they can afford to buy without considering the operational efficiency and utilization aspect. If you want to operate this machine at optimum efficiency, make sure you choose a capacity that can be easily utilized. Utilization depends on availability of raw materials as well as demand for final products in your business location.

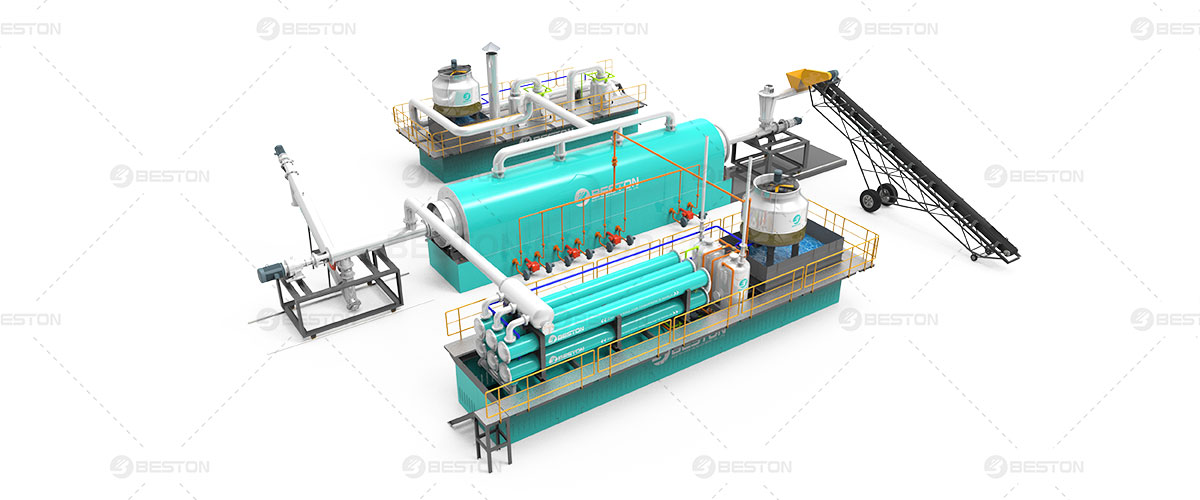

Design Configuration

These plants are sold in stationary as well as mobile configurations. Both have their own advantages. Stationary plant makes a lot more financial sense in places where availability of raw material isn’t a problem. On the other hand, a mobile plant is economically viable in places where transporting raw materials to a central location is prohibitively expensive. Mobile plants cost more as compared to stationary plants.

Brand Value

It essentially refers to the quality of materials used for making various components. Reputed brands stand behind their products and that is also true of brands in this industry. Stay away from cheap or no-name brands where the only USP is cheap price.

Automation Level

The level of automation also has a huge impact on the overall cost of a pyrolysis plant. Automation costs money but also results in fewer errors and better yield. It is better to buy a fully automated plant as it will turn out to be cheaper in the long run.

While these are some of the factors that have a huge impact on the final price of a pyrolysis plant, certain other factors also matter. For instance, you would want to buy from a manufacturer known for its after sales service. You will also need replacement parts at affordable prices to keep your operational costs in check.