Introduction to Thermal Desorption

Thermal desorption, a pivotal technique in environmental remediation and industrial processes, serves as a beacon of hope amidst the challenges posed by hazardous contaminants. This method hinges on the principle of liberating volatile and semi-volatile organic compounds (VOCs and SVOCs) from solid matrices through controlled heating. By unraveling the complexities of this process, we gain insights into its applications and efficacy in mitigating environmental pollution.

Mechanisms Behind Thermal Desorption

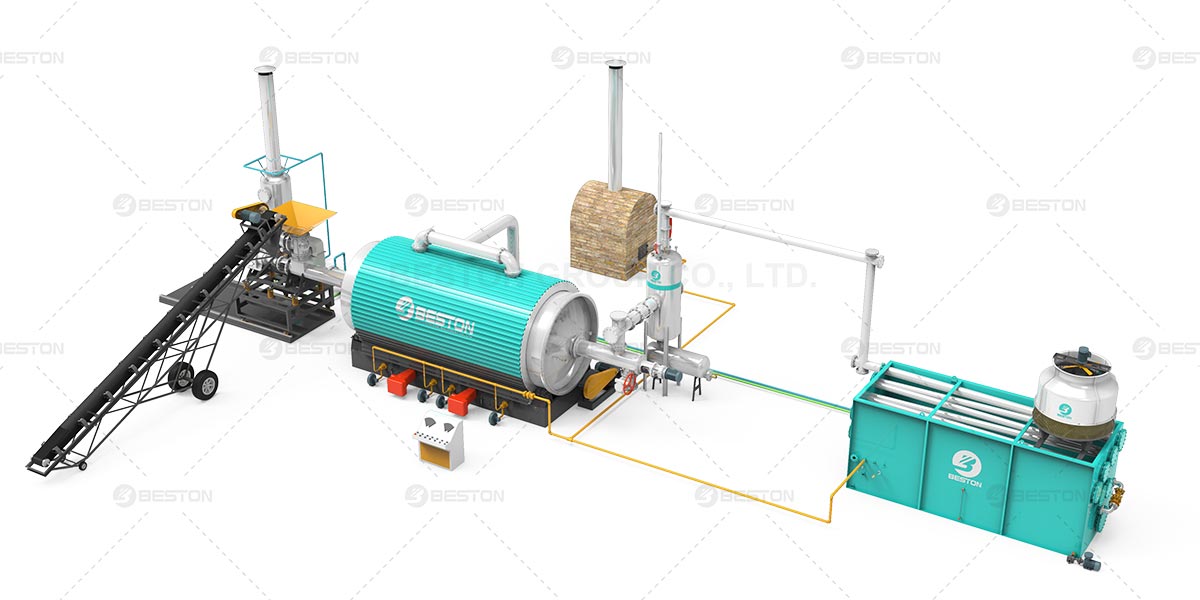

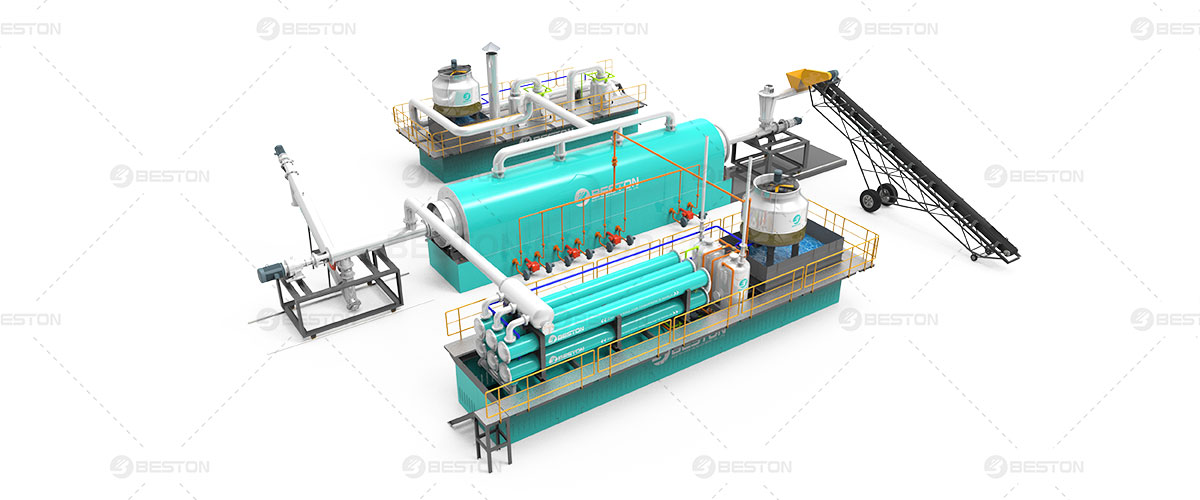

At its core, thermal desorption orchestrates a symphony of molecular liberation, guided by the interplay of heat transfer and chemical kinetics. As substrates undergo temperature elevation, the bonds restraining contaminants weaken, facilitating their transition from solid to gaseous phase. This liberation process is intricately governed by factors such as vapor pressure, molecular affinity, and substrate composition. By comprehending these mechanisms, we unlock the potential of thermal desorption in tackling diverse contamination scenarios. The thermal desorption unit device is here for your reference.

Sludge Treatment

Example: Soil Remediation

One compelling illustration of thermal desorption in action lies within the realm of soil remediation, particularly in addressing petroleum hydrocarbon contamination. Imagine a vast expanse of land tainted by decades of industrial activity, where the soil harbors a clandestine network of hydrocarbon pollutants. To initiate remediation, specialized equipment is mobilized to excavate and transport the contaminated soil to a designated treatment facility.

Within the confines of the treatment facility, the soil undergoes a meticulous preparatory phase, where it is sieved and homogenized to ensure uniform heating. Subsequently, it is introduced into a thermal desorption chamber, a crucible of controlled heat and precise engineering. As the soil traverses through this chamber, it encounters escalating temperatures, meticulously calibrated to induce desorption while preserving soil integrity. See the oil sludge pyrolysis plant here.

Under the relentless heat, hydrocarbons relinquish their stronghold on the soil matrix, embarking on a journey towards liberation. A sophisticated vapor recovery system stands vigilant, capturing the liberated contaminants and preventing their escape into the environment. This system employs an array of condensers, adsorption beds, or catalytic converters to neutralize the captured vapors, ensuring regulatory compliance and environmental stewardship.

Upon completion of the thermal desorption process, the soil emerges purified, liberated from its toxic burden. Rigorous quality control measures validate the efficacy of the remediation effort, providing assurance of environmental restoration. As the rejuvenated soil is reintegrated into the landscape, it symbolizes a triumph of human ingenuity over environmental adversity, heralding a brighter, cleaner future for generations to come. Pyrolysis also can be used to process tires, check the tyre pyrolysis plant here.

Conclusion: Unveiling the Promise of Thermal Desorption

In the grand tapestry of environmental stewardship, thermal desorption emerges as a beacon of hope, illuminating the path towards a sustainable future. Through its intricate mechanisms and compelling applications, this technique exemplifies the transformative potential of scientific innovation in safeguarding our planet. As we continue to unravel the mysteries of thermal desorption and harness its power for environmental remediation, let us march forward with unwavering resolve, forging a legacy of preservation and prosperity for posterity. More information on Beston Group here.